Hi!

This is my first post here, I am new to this amazing site. The past few days, I’ve been busy tweaking Simon to my measurements, and I think I got it now.

I was thinking: my pattern has a straight seam to connect front and back on the sides, and the front and back are narrower at the shoulders than at the waist, because my belly is dominant. And so the chest and waist and hip sizes are all the same. Now I was thinking: why do I cut three pieces and then sew the together when I can cut one large piece instead, consisting of left + back + right? If the yoke seam is straight, I could even add the outer yoke piece to the back. Right?

The paper template fits exactly. But why is this not a great idea?

From what I can gather, it will make adding the sleeves more tricky, because I’d probably have to close them first and then attach them with a round seam, because I would not be able to first attach the sleeves and then close the sleeves and front-back. OK, that’s more difficult for sure, but I’ve seen this procedure in instructions for shirts on youtube tutorials also, and it seems doable, too. They didn’t use a flat-felled seam, though. But still.

Also, I think that there are yokes out in the wild that have no cross back seam, i.e., the back and outer yoke are indeed one piece, and the inner piece is separate and then is also just open, making it an upside down pocket inside the shirt. So I see no reason not to directly attach the yoke. Even with a round back, I could just have a plaid/dart, like also for the sleeves at the wrists or the darts on the back.

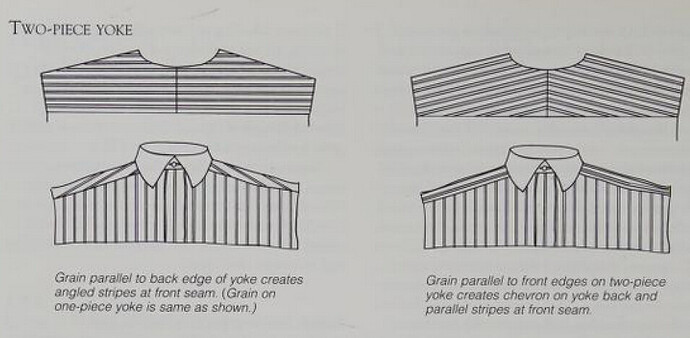

Another problem might be that the fabric is not wide enough for the whole piece. So then I would have to rotate the fabric by 90°, which would violate the grain line, I suppose. But is this really a big problem for very simple woven cotton fabric?

Hmm. Like always, I am starting to experiment even before finishing my first time I do something new… I cannot ever following instructions, it seems. So please stop me! Give me a good reason, make me understand my confusion. Tell me why this will end in an catastrophe.

Thank you!

Best regards,

Henrik